3D printing at Home, an Engineer’s dream…

Lean just beyond your edge

– David Deida The way of the superior man.

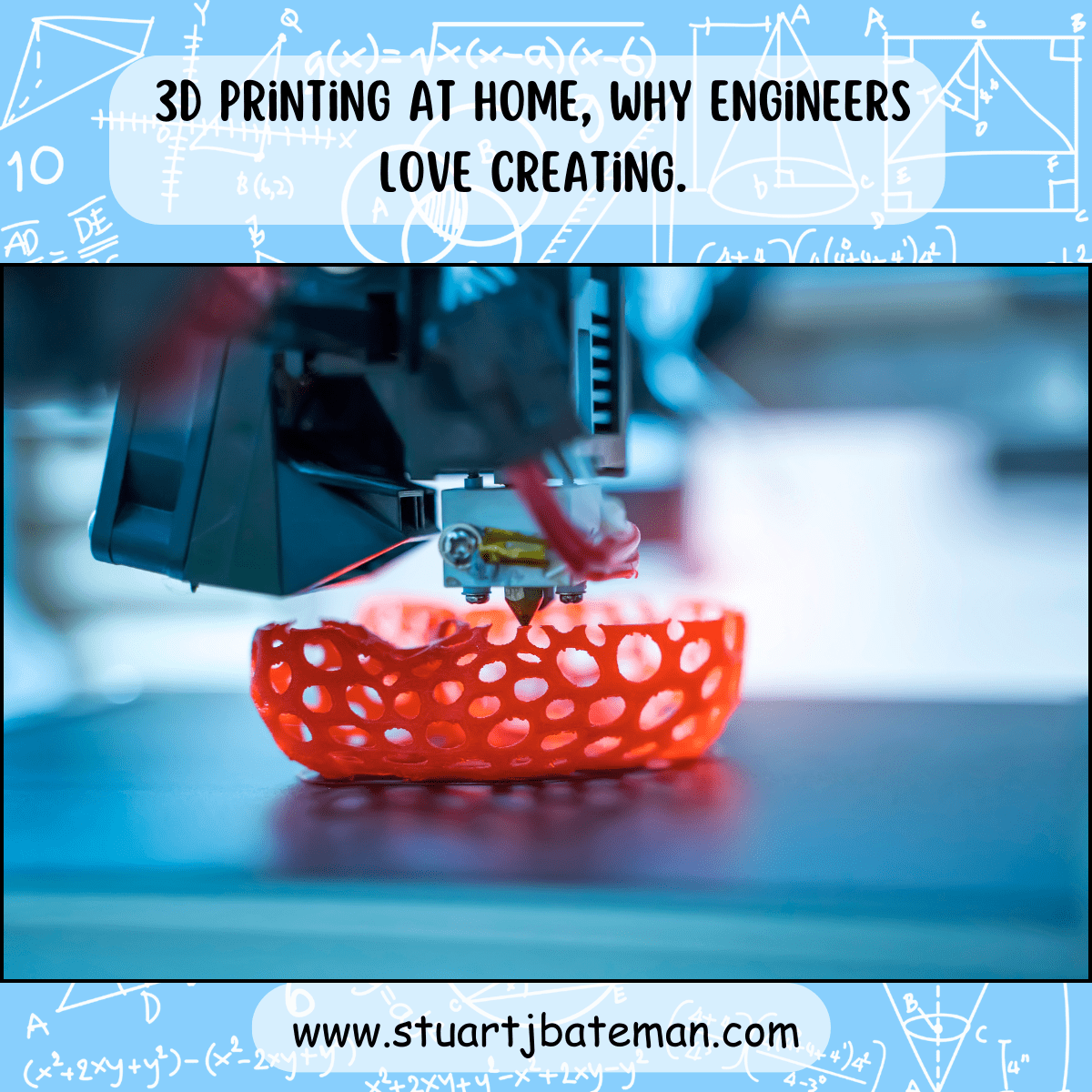

3D printing at home has opened up a whole new hobby, and for engineers it’s a great opportunity to hone our skills.

3D printing isn’t new and I’m sure you have heard of it at some point during your career, back when I was in University we had a paper stacking 3D printer which had a roll of paper that was place over an area to have a shape cut out of it and heated so the bonded glue would stick it down, then the roll would be pull to bring in a fresh area to rinse and repeat.

They have been around since roughly the 70’s (doing a quick Google search), and have been slowly getting better moving from Industry to Academia to your home. The amazing aspect of the 3D printer is that you can virtually get any design you want out of them and now for very little cost.

What are the benefits, well it’s not the speed of production, at this point in time they are very slow but it’s their flexibly that brings people in. One machine that you just need to power and add material to, to create whatever the need is.

Companies like Relativity space uses a metal welding 3D printing machine to produce their Teran 1 rockets, just one piece with very little nuts and bolts. Nasa has run competitions for companies to produce habitats for the moon and mars by just using what’s there, robots scoop up the lunar dust and produce a station capable of living in. The ISS also has a 3D printer and this has come up in the news with NASA emailing up designs to create spanners so the Astronauts can conduct experiments or fix issues.

Plastics of various types / Metals and even living tissue has been used to create structures that have practical applications (and even material that don’t, here’s a video of a channel called Teaching tech where he’s fitted a printer with a syringe to create a cake!)

Cost wise does scale quite considerably with home printer from £99 – £2500 and industrials up to £250,000 (and probably more), but there’s one more benefit which links to engineering and the home enthusiastic which is modelling your ideas and iterating them.

There are many very powerful 3D model software that you can use for free to get experience and learn from, here’s a life skill and add to that learning to print your models from a home printer like the Ender 3. It’s a technical hobby (some clever people have created businesses from them) where we can hone our skills creating stuff, we have strong interests in from the Millennium Falcon to Groot and that odd shape bracket you need to hang up those brand-new speakers for the 50’ TV.

I find having a hobby (or several that link your passion to a technical skill that can help your career or life) is great to push you outside the box to see problems from a different point of view.

The home 3D printer has taken off in recent years (since around 2012) with affordable printers that come in kit form for us to build wrong (actually they take roughly 45 mins and are very easy, even for the non-technical among us).

But why do I have one? What do I get from it for the cost? And how easy is it to maintain and troubleshoot?

As an engineer I get ideas to explore and solve problems even before I know the problems exists, most of us like to built things at home from Cars/ Robots/ Electronics/ Models/ Tools/ Furniture/ RC toys/ Bikes/ anything from wood, or have technical hobbies that demand regular trouble shooting as we can’t sit still and not think of an idea.

Why do I have one?

3D printing allows us without having a home workshop to create basically anything (I do encourage everyone to visit the sites at the end of this article to learn more). So it’s a way to take our abstract ideas and bring them into reality – then I do what I’ve spoken about before – I iterate on the idea to perfect it or PDCA if you want to link it to Six sigma improvements at the design level. Test iterate and test again, for me 3D printing allows me to exercise / develop and hone skills I use daily at work but on interesting projects to me (work has this affect to a level, but here I can explore diverse areas).

What do I get from this?

As I said at the start, my ender 3 cost about ~£200 to begin with and every roll of material about £25, depending on the material type and the supplier. But how about those upgrades I listed off? Well the most expensive was the new power supply unit at £60 (managed to burn mine out) with the rest of the upgrades from £20 to £40 each, doesn’t break the bank but it will over time. If I were to compare costs from 4 years ago then £500 spending (machine + upgrades) you’ll spend £400 on a machine with everything installed (kit form).

Engineers (and most people) like to tinker and improve so those upgrades come with their level of competence to implement them (depending on if you bought the all in one or not). This for me pushes my understanding to learn or relearn areas (I’m not heavy on electronics – too many formulas in my opinion). I research and learn before doing the upgrade since there are plenty of guides online as this hobby has a large base of users and open-source solutions that you can use, this helps stretch my boundary of knowledge and allows me to dive deeper.

How easy is it to maintain and troubleshoot?

To be honest it depends on your skills and level of competence, 99% of the issues you will face will be covered in the mentioned wealth of information found online (Google searches, YouTube and Forums).

Troubleshooting is as simple as asking a question on google – start with the symptoms and go through the points that are offered. As or maintaining the machines, FDM’s are simple. Once a month tighten the belts / bolts and grease the lead screw, every 2-3 months check the fans and nozzle for plastic build up and remove if found. Depending on how much you use the machine then replace the Bowden tube and wheels as needed (again refer to the sites I have listed for more maintenance checks).

Like all hobbies, this one has its costs which is mainly the plastic being used, but time wise I find the designing takes the most and it should be to, this is where the details are and the ideas to solve the problems can be made, so take your time and search for ideas and prompts online since you can find inspiration anywhere. Once that’s done and the printer is working, I just go make a cup of tea.

Lets sum this up.

This article started with the discussion of my hobby but it has an underlining question:

“Why do we need a hobby?”

My point I want to make is:

To create something is a worthy pass time, to develop yourself and pickup new skills makes that time spent worthwhile.

But it doesn’t have to be linked to our professional lives, here’s a link to a YouTube video where the presenter learns 92 different skills (it’s crazy)

Here’s another with Arnold Schwarzenegger in it, he talks about using every second of time given to him to develop and making use of it.

The goal is to better ourselves from an activity that’s like rest and relaxation to us, possibly even a passion.

Does a hobby have to be creative?

No, from what I understand we need periods where we can switch off the creative side, so at times I prefer to spent some hours on non-creative/productive activities.

Take a look at this video from Kurzgeagt explaining how we learn and grow (I can’t recommend this channel enough – Yes I watch YouTube, if you search well like on the net then you’ll find great free educational resources to learn from).

So to end this, I would say go create something for yourself or for others to enjoy or use (by finding a pastime to develop) because that hobby creates a better you!

(Yes, lets not forget family life comes first, just don’t forget to spent some time developing when you can).

Pro’s and Con’s of 3D printing: –

Pros

- Rapid prototyping (Not manufacturing speed)

- Cost – Less waste / carbon & physically footprint

- Flexibility – Design and space

- Tangible designs – designs that can’t be made by conventional means

- Consistent results

- Fast iterations – Reduce errors

- Accessibility – low learning curve

- Sustainable – Some materials are eco friendly

- Print on demand

- Vast open-source community and market – Models/parts / code

Cons

- Does require some technical knowledge when trouble shooting

- Hard to scale up – See print farms

- Print time vs Quality balance

- Limited accuracy on low end machines

- No one size fits all prints – still an emerging tech in homes

- Limited materials

- Restricted built sizes

YouTube channels

- Makers Muse – https://www.youtube.com/@MakersMuse

- CNC Kitchen – https://www.youtube.com/@CNCKitchen

- Teaching tech – https://www.youtube.com/@TeachingTech

- 3D printing nerd – https://www.youtube.com/@3DPrintingNerd

- Filament Friday – https://www.youtube.com/@FilamentFriday

- Void star labs – https://www.youtube.com/@ZackFreedman

Websites

- All3DP – https://all3dp.com/

- Thingiverse – https://www.thingiverse.com/

- Myminifactory – https://www.myminifactory.com/

- Maker Bot – https://www.makerbot.com/

- Ultimaker – https://ultimaker.com/

- 3Dprinting.com – https://3dprinting.com/

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.