How to overcome the headaches of Creating Effective Standard Operating Procedures (SOPs)

Image is everything on first impressions- Steve Jobs

Welcome to my latest blog post, where I’ll dive into the world of Standard Operating Procedures (SOPs) for engineers. As a chartered engineer with a passion for sharing knowledge, I understand the importance of having a solid foundation from which all future SOPs can be built. In this article, I’ll walk you through the essential elements of an SOP and provide valuable tips to streamline the process. Whether you’re an experienced engineer looking to improve your documentation or a newcomer eager to learn, this guide will help you set the ‘golden’ standard.

Before we get started, here’s another template you can use for your SOP’s from the CI Toolkit, or just copy mine from below!

How I create a Standard Operating Procedures

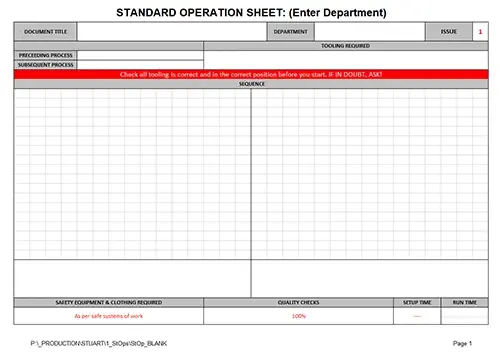

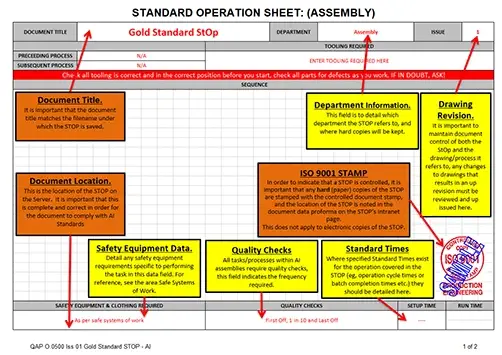

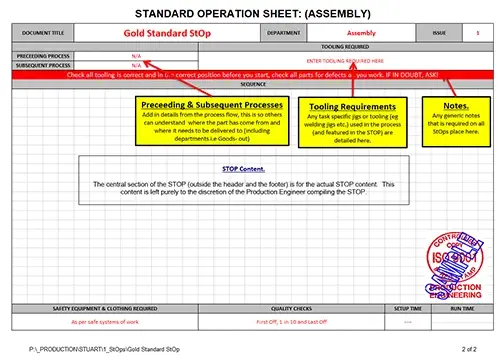

I usually like to develop a working blank from which all future Standard Operating Procedures can be copied from, this is just time saving, but it can help others to follow the ‘golden’ standard that you set. It’s also easier to teach others how to create SOP’s from using a template.

- So what needs to go on an SOP? Well this is the basic information I put on:

- Document title – Keep it simple and unique

- Department – This is the process owner that the SOP belongs too, remember they own the SOP’s so ultimately they need to manage and update it when needed.

- Issue – Like drawings, SOP’s will get updated and it’s important to follow the same document control to ensure everyone has the most recent copy (and that the old revisions are recorded as in what you changed from one to another).

- Preceding process – This one and the next are really something I like to have and not really needed, it is mainly for new starters so they can learn where the part / product needs to move onto next.

- Subsequent process – Same as above.

- Tooling Required – So any special tooling including jigs & fixtures, glues / tape etc.. Goes in this box. It allows the operator to see what’s required and highlight to supervisors if anything is missing.

- Safety equipment & clothing required – This is mainly for fabrication and machine shops (and other dangerous process areas), all PPE is to be used and adhered to, following the UK HSE guidelines which your company will have their own guidelines that complement the HSE ones. I mention safe systems of work, which is an audit done by engineers / process owner to identify the risks and what PPE mitigates / eliminates them.

- Quality checks – This is where we add in how often the checks on dimensions / features need to happen. These areas can be highlighted on the Standard Operating Procedures, but we identify them by discussing and involving the engineering department on the SOP generation (by asking what are the critical dimensions). Also by involving the operators, some may know from experience what to check often for.

- Options common ones are:

- 100%

- 1 in 10

- First off, last off, random

- Options common ones are:

- Setup time – This depends on how your company likes to record and display timings, but here you can state the average time it takes to setup for the job.

- Run time – This is the cycle time.

- Main Sequence – The main boxes on the sheet are for the sequence of tasks needed for the job. Here I like to add in more pictures than description, as it’s easier to point and highlight details on the picture and add notes directly to it. In the descriptions you can refer to part numbers and names before details on how they go together.

- TIPS –

- Used excel, it’ll make your life easier

- Create a template

- Where possible create a spreadsheet and hyperlink all your SOP’s in a searchable list, make it easier to control and update (less paper as well), but it needs a few PC’s on the shopfloor for quick access.

- Make sure operators know that they own the Standard Operating Procedures, it’s down to them to read and highlight changes, it’s not set in stone, but changes are assessed to ensure they are repeatable and agreed upon (and in some cases they will need to be timed to ensure takt is met).

- Used a camera to record the process, if operators object then discuss that the video can be destroyed afterwards, and/or you’re just recording the process and not them.

- Sit down with several operators who do the process and ask them for the instructions – spend time with them and write down their notes, then go through the actual process.

- Either with the video or while watching, you can time the elements to capture the time study details for the VSM later.

- At the base of the SOP, add in the computer file path, this allows us or others the find the excel file to edit later. This is to help when people move on and others have to take over.

- If you need to create physical copies of SOP’s print them and encapsulate them.

- If storing SOP’s on operator PC, create PDF’s so that you can control/ limit the editing (again so we can assess the changes)

Conclusion

In conclusion, crafting effective Standard Operating Procedures is not just about ticking boxes; it’s about creating a reliable roadmap for your engineering processes. By following the steps outlined in this guide, you can ensure that your SOPs are clear, comprehensive, and capable of guiding both seasoned professionals and newcomers.

As you embark on this journey to enhance your SOPs, remember that continuous improvement is key. SOPs are living documents that should evolve alongside your processes. Encourage your team to take ownership of Standard Operating Procedures and be open to feedback and change. By doing so, you’ll contribute to a culture of efficiency and excellence within your engineering department.

If you found this article helpful, please consider sharing it with fellow engineers and on your social media channels. Your knowledge and experience can make a significant impact on the engineering community. Let’s work together to raise the standard of SOPs in our field and empower the next generation of engineers.

Thank you for joining us on this Standard Operating Procedures exploration. Stay tuned for more insights and knowledge-sharing on our website. If you have any questions or need further guidance, don’t hesitate to reach out. Happy engineering!

If you’re looking for more information on SOP’s here are some recommendations:

- Effective SOP’s – Giles Johnston AmazonLink

Internal – Lean

Check out more Lean Manufacturing topics:

- What is Flow Production? Complete Implementation Guide 2025

- How to create a Value Stream map

- How to…use the Theory of Constraints (TOC): Streamlining Production

- Success Story: Transforming Workflows with Continuous Improvement

- How to..Conduct 3S

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.