Stuck with creating flow? Here’s why you need to learn Line balancing

You don’t rise to the level of your goals, you fall to the level of your systems. – Atomic Habits

Line balancing at StarBase Texas

Have you seen the latest Tim Dodd’s video “First look inside’s SpaceX’s Starfactory w/Elon Musk”?, it’s a must watch as Elon talks about Line balancing. Apart from me being a space nut, there were a few golden nuggets in there and one section about manufacturing Starship that I found very interesting.

If not you can find part 1 here:

One line that Elon states that “Continuous linear flow is key” really brings to light that production flow can be used from making small components right up to Starships themselves, but what does he mean?

Elon adds that “having all the stages produce work at or around the same time allows for the work to move along at a reasonable pace – no conveyor line (referring to Henry Ford) needed”.

Line Balancing

There’s a tool that you can use to balance work station jobs and it’s effectively called – Line balancing.

I’ve used this before at Stannah and AI.

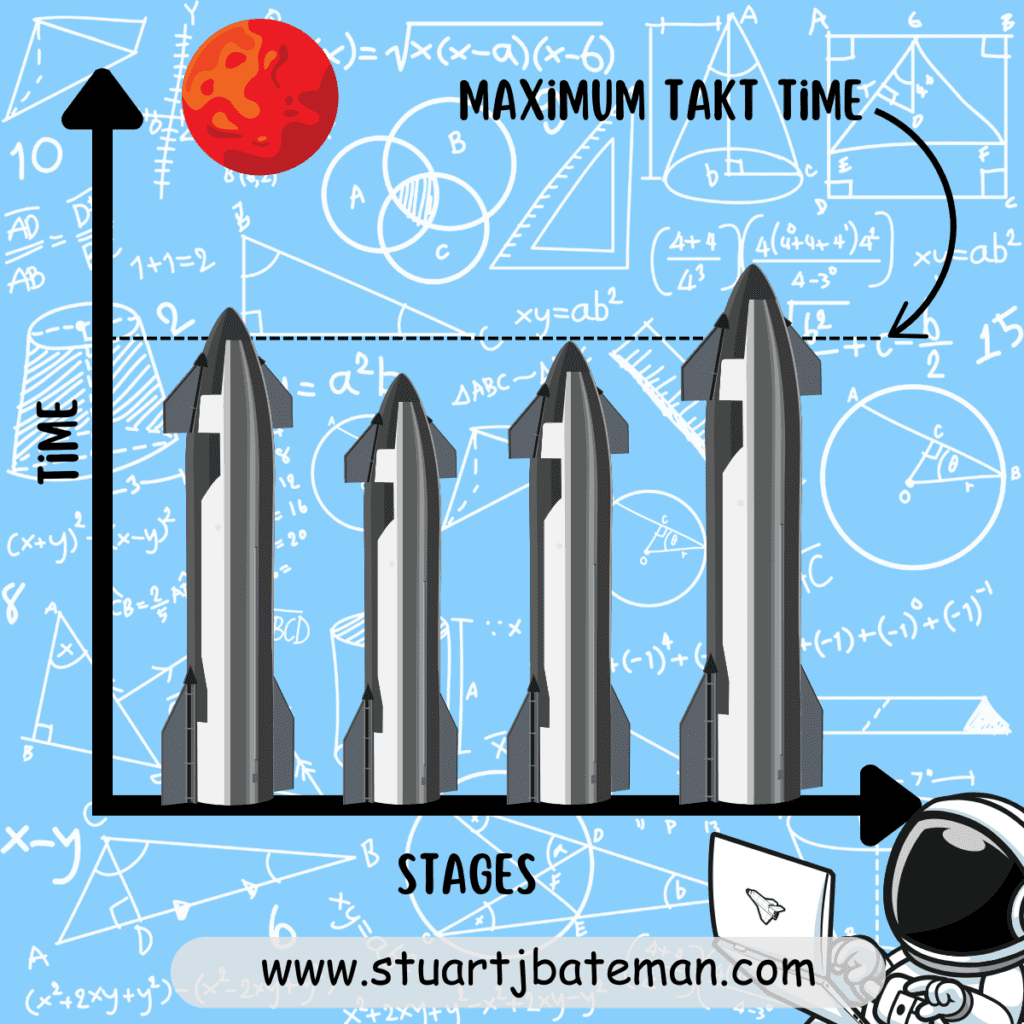

Simply put, line balancing is where you use the customer demand rate to set the maximum time allowed to produce the product, but you can go one step further and set this time to each stage of your production line (per product), so if your line has 10 machines/stages/stations then each one is allowed to produce up to that time.

But to account for inefficiencies we use 85% of that time.

The calculation

Let’s do a quick calculation based on 100 starships being produced per year at Starbase.

Ok, let’s assume that the factory is 24/7 so that’s a production time of 1440 mins per day, and to produce 100 Starships in one year means we need to produce one every (365/100 = 3.65 Days)

So that’s 1/3.65 = 0.274 starships per day at 1440/0.274 = 5255.4745*0.85 = 4467.1533 mins per ship.

That means no stage/process can take longer than 4467.1533 mins or 4467.1533/60=74.4526 hours that’s quite long for standard manufacturing, but Elon wants to get to 1000 ships per year!

Here’s a visual on what a line balancing chart would look like:

What to do, to ‘Balance’ each stage in the production line

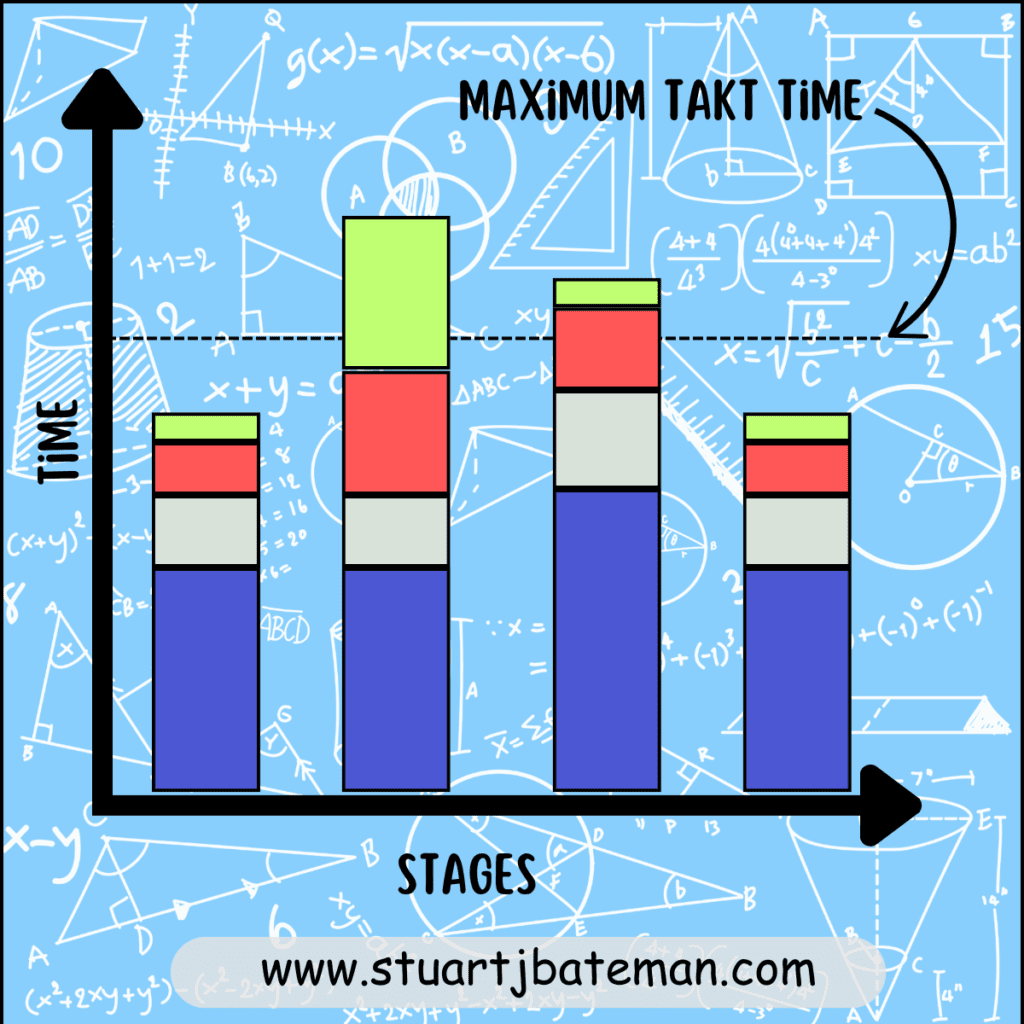

Now it’s a case of reviewing each stage to understand how long they take, and if they take longer we can focus on the tasks and break them down into their elements to time them and see if they can be moved to another stage (or eliminated).

Looking at each stage we need to create a work combination chart so that we can understand all the elements that make up the stage so that they can be timed, here’s what one looks like:

With this information, we need to convert it into our bar charts in the form of stacked bar charts, this allows us to see each step in the stage and their proportion to the overall task time against the takt time, and that looks like this:

You can use excel to help you balance the line, by setting up the tasks and times along with the stages, you can have the chart that dynamically moves the elements around between the stages to visually show you when they all fit under the takt time (but remember, some tasks will have constraints and need to be directly after or before other elements), be careful not just to move everything, consider eliminating elements as well.

Conclusion

Musk isn’t wrong, setting up a manufacturing process is much harder than developing the ship!

Line balancing isn’t difficult, it can become a tool to highlight to us what further improvements are required before you can achieve flow at the rate governed by the takt time.

Remember not to make the processes up stream much faster than the takt time, or else you risk creating a constraint downstream at a stage where you’re struggling to reduce or move the elements around.

Resources:

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.