What are the essential technologies for modern product engineering?

Any sufficiently advanced technology is indistinguishable from magic.

Arthur C. Clarke

Essential Technologies for Modern Product Engineering

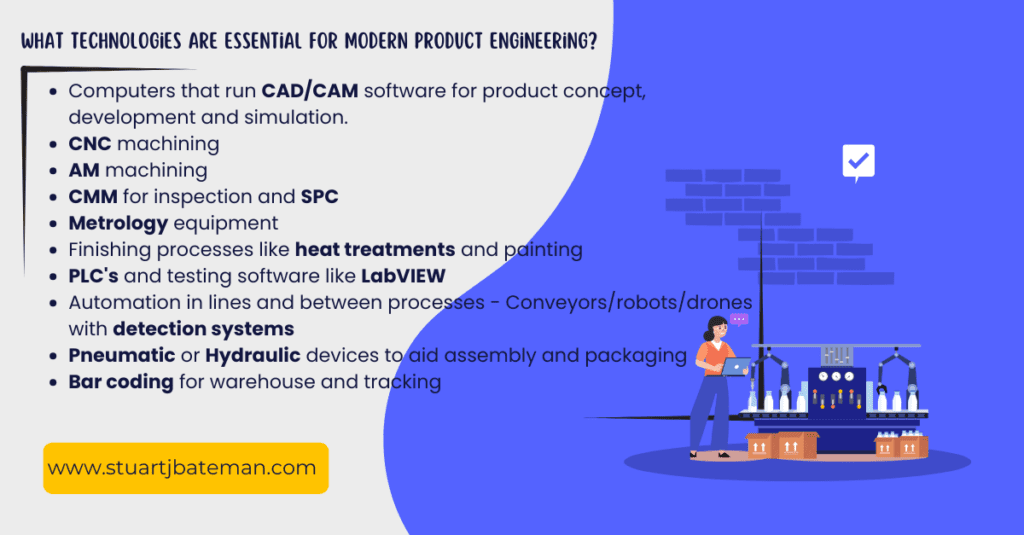

It’s worth noting that, as a Production Engineer, I see some of the stages and processes outlined below as potentially wasteful—but that’s a discussion for another time. Drawing from my experience in various manufacturing environments, I’ve broken down Essential Technologies for Modern Product Engineering into stages required to take a product from concept to shipping. Please feel free to suggest any additions!

Additionally, with the rise of technologies like Additive Manufacturing (AM), Artificial Intelligence (AI), and Industry 4.0, traditional systems are evolving to become more interconnected. This integration enhances automation and enables capabilities like remote monitoring, lights-out manufacturing, and detection systems with auto-correction.

Stages: From Concept to Shipping

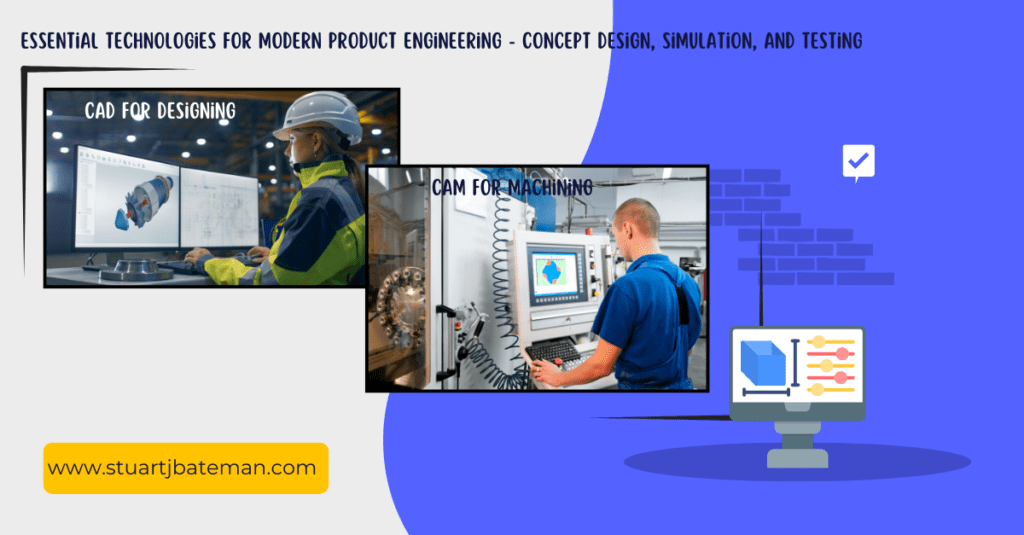

1. Concept Design, Simulation, and Testing

- Software Advancements: The backbone of modern design lies in software, enabled by increasingly powerful computers.

- CAD Systems: Tools like Fusion 360, SolidWorks, CREO, and CATIA have been staples since the 1980s. These systems allow engineers to design virtually, test fits, check for tolerance clashes, create flat patterns, and simulate motion and stress (FEA). They also provide libraries of off-the-shelf components for seamless integration.

- CAM Systems: These extend CAD capabilities by creating CNC machine programs. Programmers can build tool libraries, simulate fixture setups, and optimize tool paths, minimizing cycle times and tool stress. While CAM software offers significant automation, experienced programmers still play a critical role in tool selection.

2. Manufacturing and Production

- CNC Machining: Traditional CNC machining remains vital for most products, though AM is beginning to offer alternatives for complex geometries and high-performance parts (e.g., aerospace components). CNC systems like Fanuc, Mazatrol, and Heidenhain are foundational for high-volume production.

- Additive Manufacturing (AM): AM allows rapid prototyping, cost-effective iteration, and the creation of geometries impossible with traditional machining. While scalability and speed are current limitations, its role in engineering continues to grow.

3. Treatments

- Advancements in material science have been complemented by innovations in finishing processes, which modify mechanical properties or aesthetics. Examples include:

4. Inspection

- Coordinate Measuring Machines (CMMs): A staple in manufacturing for decades, CMMs offer micrometre-level accuracy and repeatability. They enable in-house labs for precision inspection and act as master gauges for calibrating other equipment, reducing overall calibration costs. Modern CMM software also integrates with tools like Excel to drive Statistical Process Control (SPC) and generate data visualizations.

- Metrology Equipment: Tools like verniers, micrometres, and gauges allow operators to perform in-process inspections, providing immediate feedback and enabling machine adjustments. Coupled with SPC, operators can track trends and address variables affecting quality.

5. Assembly and Packaging

- Automation and Testing: Programmable Logic Controllers (PLCs) and software like LabVIEW are increasingly used in assembly lines, especially for electrical components. These systems guide operators, record test results, and ensure traceability through barcodes.

- Ergonomic Aids: Pneumatic and hydraulic devices reduce worker strain by handling awkward or heavy loads during assembly and packaging.

6. Transportation

- Effective transport solutions ensure seamless movement of components and finished products between facilities or to customers. They range from the simple everyday forklift truck to the more complex automated and bespoke conveyor systems.

7. Storage and Sorting

- Barcoding Systems: High-volume production demands efficient tracking. Barcoding systems monitor stock transactions, track work-in-progress, and optimize warehouse storage. This ensures precise production quantities and smooth logistics.

While this overview focuses on general-purpose essential technologies, industry-specific regulations and business needs may necessitate additional tools or processes. However, this only covers the developments over the last 60 years of manufacturing and as I mentioned earlier, a lot of these systems will be integrated into autonomous systems that both allow remote work and controls include full automation that increases capacity (lights out machining) that can bring down the cost to make. There are challenges ahead to achieve this, but soon we’ll need the next big innovation and that could come from AM.

I hope this provides a clear and comprehensive view of the essential technologies in modern product engineering. Let me know if there’s anything you’d like to expand on!

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.