You really need to apply SMED and Poka Yoke Thinking in Fixture Design

The only way to prevent mistakes is to prevent them from happening.

Shigeo Shingo

SMED and Poka Yoke thinking in fixture design

Manufacturing, integrating SMED and Poka Yoke thinking in fixture design can significantly improve changeover time, reduce operator error, and boost production efficiency. These two powerful Lean tools—SMED (Single-Minute Exchange of Die) and Poka Yoke (Mistake-Proofing)—are often underutilised when developing jigs, fixtures, and gauges. This post shares my experience applying both principles throughout the design process, offering practical insights and tips to help other engineers.

Before getting stuck into this piece, I’ve previously written about the best way to design jigs/fixtures and gauges: https://stuartjbateman.com/designing-jigs-fixtures-the-right-way/

My Background

With a background in CNC machining and Lean manufacturing, I’ve designed more than 1,500 fixtures over the last 11 years at companies like AI, Stannah, and Lewmar. My designs support a wide variety of production systems—from one-off prototyping through to high-volume automated lines. That experience has taught me that efficiency and error-proofing should be embedded in design from day one.

More on me and my daily work life: https://stuartjbateman.com/a-day-in-the-life-of-a-production-engineer-2023/:

What is Poka Yoke?

Poka Yoke, meaning “mistake-proofing,” is based on the belief that “if it can happen, it will.” People make mistakes, often due to fatigue, boredom, or process complexity. Poka Yoke uses design features to prevent these mistakes from occurring or to immediately detect and correct them. In fixture design, this might mean using asymmetric locating pins to prevent loading parts the wrong way, or incorporating sensors to detect missing components before a process starts.

More on Poka-yoke: https://stuartjbateman.com/5-easy-ways-to-integrate-poka-yoke-design-thinking-into-your-solutions/

What is SMED?

SMED (Single-Minute Exchange of Die) is a Lean method that reduces setup and changeover time. Originally developed for press tooling, it now applies broadly to machining, assembly, and packaging.

The key idea is to separate tasks into two categories:

- External tasks: Performed while the machine is running.

- Internal tasks: Require the machine to be stopped.

Once separated, internal tasks are then targeted for conversion to external, thereby reducing downtime. For example, pre-setting tools offline instead of during machine downtime, or designing fixtures that don’t require manual adjustment between batches.

More on SMED: https://stuartjbateman.com/how-to-implement-smed/

How Have I Used It?

I regularly bring both concepts—SMED and Poka Yoke thinking in fixture design—into play during the industrialisation phase of projects. Once machines are installed and operational, the real learning begins. You must understand how the part will be made, how to hold it, what the machine’s constraints are, and how the design meets the required takt time.

After setting up a process, I observe its performance and identify bottlenecks or risks. These insights then guide the fixture design phase, where I eliminate internal steps, reduce variation, and simplify operator tasks.

How to Implement SMED Thinking

The core of SMED is observation. Stand at the machine and ask:

- What tasks could be done while the machine is running?

- Which steps absolutely require machine downtime?

- Are any of these activities necessary at all, or are they driven by old habits or equipment limitations?

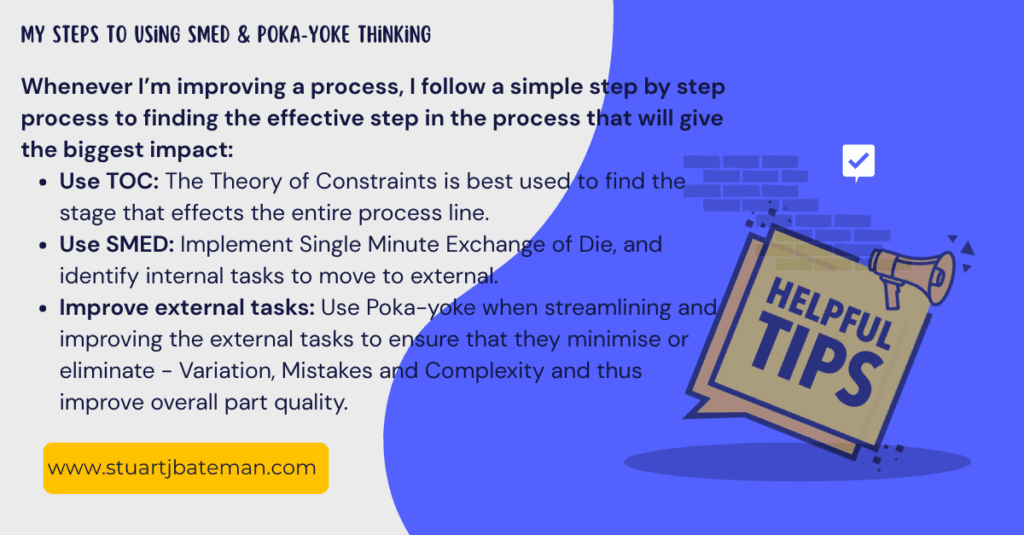

Prioritise where you apply SMED by identifying the system constraint—use Theory of Constraints (TOC). Break the bottleneck first; that’s where your optimisation efforts will deliver the biggest gains.

How SMED and Poka Yoke Influence Fixture Design

Combining SMED and Poka Yoke thinking in fixture design is especially powerful when converting internal tasks into external ones. Many internal tasks—like alignment, clamping, or calibration—require custom solutions to streamline or automate them.

In most cases, a fixture becomes the answer. It might be redesigned from scratch or adapted to remove the need for manual steps. My fixture designs always include input from Process FMEAs, operator interviews, NCR trends, and on-the-ground observations.

Key Lessons from SMED (Shigeo Shingo):

- Clamps only need to apply pressure on the last turn—simplify tightening mechanisms.

- Remove adjustments—use fixed positions or limit the number of variables.

- Standardise fixture sizes per machine—minimises complexity and setup effort.

- Design for one-handed clamping—improves speed and ergonomics.

Key Lessons from Poka Yoke:

- Investigate past NCRs, near-miss reports, or operator feedback to identify mistake modes.

- Evaluate how easy it is to get a process wrong—simplicity is key.

- Visit the Gemba—real experience using the process reveals gaps designers might miss.

- Look at task frequency—repetitive steps are more prone to errors due to complacency.

Design Principles I Follow

When applying SMED and Poka Yoke thinking in fixture design, I focus on creating tooling that is:

- Simple to operate, clean, and maintain

- Quick to set up or swap (even mid-process)

- Safe, by avoiding pinch points and unstable configurations

- Consistent, using standard hole sizes and shapes for interchangeability

- Process-aligned, by removing redundant steps and reducing operator decisions

These practical points represent the real-world application of SMED and Poka Yoke thinking in fixture design, balancing usability with process control.

Practical Design Tips

- Build gauging into your fixture: Include 100% in-process inspection features.

- Design with the process in mind: For CNC, ensure swarf is removed easily and coolant flow isn’t blocked.

- Think about safety: Avoid finger traps and unstable placements.

- Keep it simple (KISS): Remove unnecessary parts, use standard tooling, and aim for universal usability.

- Test often: Use CAD for concept validation, but always prototype and collect operator feedback before release.

My Experience

Designing over 1,500 fixtures has taught me that operator feedback, simplicity, and process insight are everything. The most effective designs are the ones that prevent error, reduce downtime, and improve changeover time. My success is rooted in consistently applying SMED and Poka Yoke thinking in fixture design, supported by close operator collaboration and structured observation.

One simple fixture I designed was for a milling job that had to orientate the part at 12.5 degrees to allow for a slot drill to plunge down into the part to create a feed ramp, I was mindful of several points:

- Swarf and coolant

- Orientation

- Correct location of part

- Single point camping

- Gauging the OD

The design I came up with had large slots to allow swarf and coolant to flow, escaping the fixture, a dowel to locate the part (asymmetrical design) this highlighted to the operator the part was loaded incorrectly, the part was held in a ring that was machined to a tighter tolerance to gauge the OD and the clamping used a dowel to engage with a feature on the part that would then allow the clamp to fit into place with one hand.

That solution didn’t come from using TOC and SMED, rather it was a NPI task that needed a production fixture to be designed, tested and validated.

An example of using TOC and SMED to highlight a potential opportunity came when I was implementing a product production line of 10 stages, one stage about 3/4 the way through was causing a bottleneck every time the process had to changeover from one variant of the product to another, this required setting up of a bespoke designed reamer which would take 1 – 3 hours depending on the skill of the operator and a little luck.

The solution was simple, to have all the required special reamers in the machine, this meant that the only time you have downtime was to change out worn or broken tooling, this saved manufacturing time and enable quicker changeovers, I stress the simple idea which wasn’t to move an internal to external task but rather to take advantage in improving the machining process to reduce the requirements of the other tools (some were eliminated others were merged into one tool) to give us the space to have the reamers all present.

The result was to reduce the cycle time from 55 mins to 27 mins and eliminate the changeover time for variants to just the standard setup which took 5 mins. This illustrates that processes can be improved by thinking outside the box, but having knowledge of Poka-yoke, SMED and TOC allowed me to see the problem from a different angle.

More on TOC: https://stuartjbateman.com/how-touse-the-theory-of-constraints-toc-streamlining-productivity/

Round up of this method

SMED and Poka Yoke are more than just Lean tools—they’re design principles. If you want robust, operator-friendly jigs and tooling, you need to incorporate SMED and Poka Yoke thinking in fixture design right from concept. Focus on simplicity, mistake prevention, and process alignment, and your tooling will support both productivity and quality.

Recommended action

Review your latest tooling project—how could SMED and Poka Yoke thinking in fixture design make it simpler, safer, or faster? Whether you’re designing a new fixture or improving an old one, look at it through this lens and see what opportunities emerge.

Further Resources

SMED (Single-Minute Exchange of Die)

- LeanProduction.com – SMED Overview

- SafetyCulture – SMED: Lean Tool for Manufacturing

- SixSigma.us – SMED in Lean Six Sigma

- Gemba Academy – What is SMED?

- MaintainX – Understanding SMED

Poka-Yoke (Error-Proofing)

- Tulip – The Ultimate Guide to Poka-Yoke

- SixSigma.us – Poka-Yoke in Six Sigma

- ASQ – Mistake-Proofing

- Kanban Zone – Poka Yoke in Toyota Production System

- FourJaw – Implementing Poka-Yoke

Resources (External) – Engineering Design

Here is a list of resources I find particularly usage in any design project I’m doing:

GD and T Basics – A one stop shop to list and understand all the Geometric tolerances used today in industry, with simple explanations (some are long) with illustrations to demonstrate.

Learn Mech – As it says on the tin, head over here to dive into the many different mechanical examples shown and explained on this site.

My Physics Lab – A great interactive website that teaches you many (if not all) the mechanical principles and physics.

Engineering Toolbox – A true repository of engineering (all fields) knowledge, go jump down that rabbit hole!

Engineers Edge – Just like the Engineering toolbox, this site has calculators for many of the engineering principles it talks about, great to working out things.

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.