How can you determine if a project has been over engineered or under engineered?

To focus on what can be controlled – The obstacle is the way

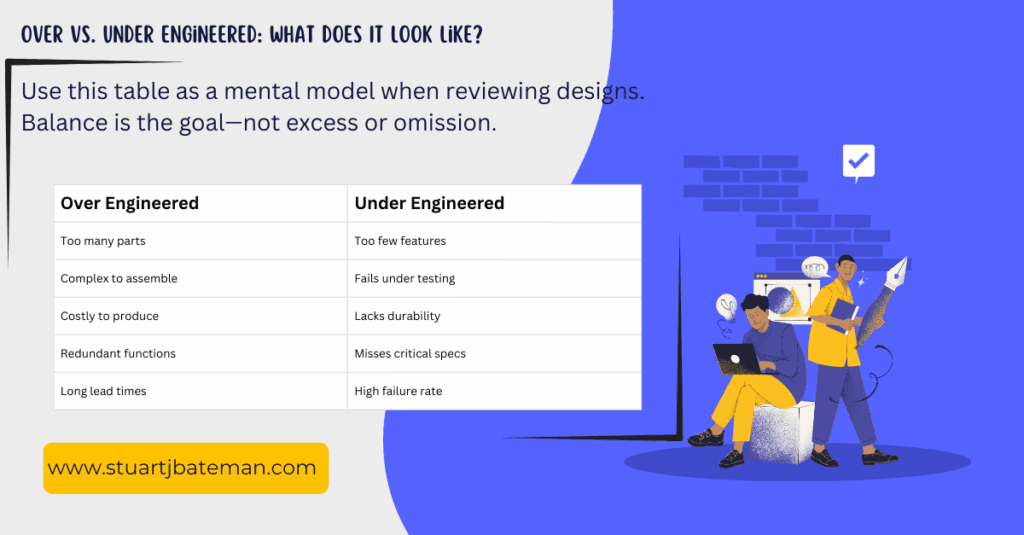

Over engineered or Under engineered, you decide

The question of over engineered vs. under engineered essentially revolves around simplification and rigorous testing. Elon Musk frequently addresses this in his discussions, notably on Tim Dodd’s YouTube channel.

Today’s designs are often overly complex, leading to increased production costs, longer lead times, and higher costs to the customer.

Here’s an example of a simple engineering project I did at home to develop a bracket to hold a GoPro as a Baby monitor, the process of developing and conducting this project is far simpler than others in industry, like for example building a ship.

Over Engineered Parts:

From the Raptor engine to Tesla cars, Elon has driven both companies towards reducing complexity. For instance, he recounts a story about a Tesla car plate in the footwell that no one remembered the purpose of. By systematically removing components or features until the product ceases to function correctly, and then reintroducing the last necessary component, one can identify and eliminate unnecessary parts. This approach led to the discovery that the footwell plate was redundant. After identifying unnecessary components, they are designed out of the final product. This method reflects the evolution from Raptor 1 to Raptor 3.

Under Engineered Parts:

To identify under-engineered parts, rigorous testing is essential, whether through CAD simulations or real-life scaled testing against original specifications. If the product passes these tests, the original design specifications and requirements should be reviewed and revised.

My 5 Steps to Prevent Over Engineered and Under Engineered:

- Review the Project Scope:

- Conduct a detailed analysis of what is needed vs. what is achievable in terms of cost, time, and technology.

- Test Each Feature:

- Produce prototypes using rapid testing platforms like 3D printers. Print, test, and collect data to evaluate performance.

- Iterative Design Review:

- Regularly revisit and review the design throughout the development process. Involve cross-functional teams to gain diverse perspectives and identify potential over- or under-engineering early.

- Stakeholder Feedback:

- Gather input from all stakeholders, including customers, end-users, and team members. This feedback can highlight practical issues and unnecessary complexities that might not be evident from internal reviews alone.

- Continuous Improvement:

- Implement a feedback loop from the testing phase back into the design process. This involves not only correcting identified issues but also refining the design criteria based on insights gained during testing.

There are tools like design evaluation matrix that can help you asses the designs at any stage before you settle on the final product for production, here’s a blog post explaining that tool: https://kayemdesign.wordpress.com/2013/10/29/matrix-evaluation-1-project-3/

While the title hints at projects, I’m talking about the solutions (products) that we design to solve the problem we or the customer has. It’s important to note that all projects that you will work on will end up being complex and that’s fine, you need something in place and working even if it’s complex and difficult for others to follow, it’s normal for it to happen the real work as I’ve mentioned is to simplify it which is where some true inspirations in designing comes in.

If you need some pointers in designing, check out my Engineering design guidelines.

Some resources:

- The Art of Simplifying in Engineering

- IF I COULD ONLY DO 3 THINGS TO SIMPLIFY A DESIGN, WHAT SHOULD THEY BE?

Resources (Internal) – Engineering Design

Liking this post? there’s more on this subject if you want to learn more:

How to use the Engineering design process

Why do engineers constantly use NDT?

Tighten tolerances and the costs go down?

How important is knowledge of materials for mechanical engineers?

You really need to apply SMED and Poka Yoke Thinking in Fixture Design

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.