How to really conduct Time studies

If you can’t describe what you are doing as a process, you don’t know what you are doing.

– William Edwards Deming

Time studies are the foundation of Lean methodology and often the first technique an industrial engineer learns. Without capturing time data from the shop floor, we cannot measure throughput, value-added (VA), and non-value-added (NVA) time. Without this data, we cannot construct an accurate value stream map (VSM), which is essential for driving continuous improvement activities.

This article is part of the lean manufacturing series, if you want to get a good understanding of where to start, I recommend the following:

- How to create flow in the workplace

- How to..Conduct observational studies

- How you should start your lean journey

What Is a Time Study?

A time study is an observational method that brings the engineer to the shop floor to study a process, break down a stage into tasks or elements, and understand the steps and timings involved. It’s also a tool to observe the variation between different operators, as their performance and approach can vary. Repeating time studies across different individuals is essential to account for these differences.

The goal is to capture reliable cycle times for each step so that you can calculate:

- Current throughput

- Takt time (vs. customer demand)

- VA/NVA ratios

- Process constraints and inefficiencies

My Introduction to Time Studies

I first encountered time studies at Stannah. A senior manufacturing engineer, previously from the automotive sector, shared not just the technique but also provided templates and a clear method.

I started with press brake machines, focusing on runners, repeaters, and strangers (pro tip: ignore the strangers). With hundreds or thousands of repeat part numbers, I organised several engineers to assist on Fridays with data collection. We created a model covering as many parts as possible. This allowed us to:

- Establish a benchmark

- Calculate takt time

- Compare actual vs. required throughput

- Analyse VA/NVA time for improvement planning

My Method for Conducting Time Studies

If you’re new to time studies or refining your approach, consider the following structure:

- Select the Process

- Preferably the first stage in a chain of operations.

- Ensure the operator is experienced (6+ months).

- Prepare Materials

- Stopwatch with a lap function.

- Time study sheet (with a layout diagram).

- Video camera (optional but highly recommended).

- Initial Observation

- Watch the process fully without timing.

- Document all steps you observe.

- Break steps into time-able elements (start/stop points defined clearly).

- Time the Process

- Time at least 5 full cycles.

- If results are stable (within ±20%), that’s sufficient.

- If times vary, capture 10 cycles.

- Note Operator Variability

- Record signs of speeding up or slowing down.

- Average the Observed Times

- Take the mean time for each element.

- Apply Allowances

- Use standard allowance percentages for:

- Personal needs (e.g. 5%)

- Fatigue (e.g. 4%)

- Delays (e.g. 5%)

- These account for real-world conditions, add up all the allowance % to express total allowance e.g. 14% from the above examples

- Use standard allowance percentages for:

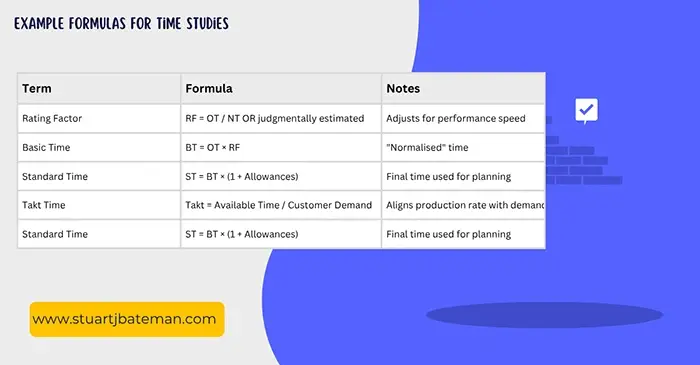

- Calculate the Performance Rating (Rating Factor)

- This adjusts for how fast/slow the operator is compared to standard.

- Watch the operator and determine the amount of effort they are putting into the tasks, if they are pushing themselves then the % is over 100% so e.g. 120% or 1.2. If they are slow (they could be new or lack experience) then the % could be 85% or 0.85.

- Determine Basic Time and Standard Time

- Basic Time (BT) = OT × Rating Factor (e.g 120 secs x 1.2 (120%) = 144 secs)

- Standard Time (ST) = BT × (1 + Allowance %) (e.g. 144 secs x (1 + 14%) = 144 x 1.14 = 164 secs)

- Enter Results into a Spreadsheet

- Include all operators assigned to the stage.

- This will help analyse min/max throughput.

- It also allows you to calculate Takt time.

Example Formulas for Time studies

How I Improved the Process

Recording video of the process was a game-changer.

It:

- Helps operators act naturally

- Captures details that are often muscle memory

- Allows repeat reviews for better accuracy

I used old cameras to record 10 processes and reviewed the footage later. This sped up data capture, though review time remained the same. I also experimented with letting operators log their own process times—useful for rough bottleneck identification, although less accurate.

Ensuring Data Quality

Key questions to ask before collecting data:

- Is the operator capable and consistent?

- Is the SOP being followed?

- Is the process stable and repeatable?

- Are start/stop points clearly defined?

- Do you have enough cycles and parts?

- Is the process worth videoing?

- Is there time and space to record reliably?

Reduce variables as much as possible for clean data.

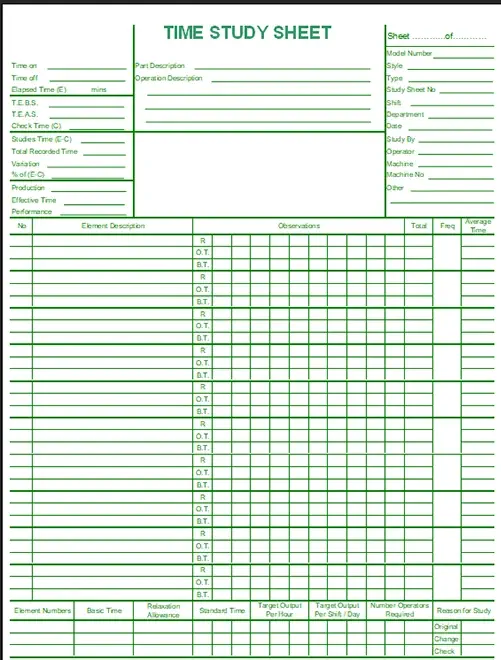

Templates I Use

Here is the modified template I used from Stannah. It includes:

- Step breakdown

- Layout sketch

- Space for multiple cycle timings

- Averages and rating calculations

- Observations box

Resources to learnt from:

This here is a great site that really help me to learn the finer details for this process:

https://vishalshindeblog.wordpress.com/wp-content/uploads/2017/03/unit-iii-ie.pdf

Then there are:

- Industrial Engineering Unit III PDF (Detailed)

- How to Conduct a Time Study – WikiHow

- Retrocausal Blog: Manufacturing Time Study

- Amper Blog: Time Study Best Practices

- ISSSP: Time and Motion Studies Overview

- IE 101 Slide Deck

- General Time Study Slide

On your Marks! Get ready to do your Time studies!

Time studies are a critical foundation for any lean transformation. Getting this data wrong can skew your entire value stream map and derail improvement efforts. Use the steps above to build your understanding and get it right.

Try involving multiple people in the timing process and compare your results—a simple form of Gage R&R—to spot outliers or missed elements. Once confident in time studies, you’re ready to move on to Activity studies, where we begin to map actual resource usage across the value stream.

Internal – Lean

Check out more Lean Manufacturing topics:

- What is Flow Production? Complete Implementation Guide 2025

- How to create a Value Stream map

- How to…use the Theory of Constraints (TOC): Streamlining Production

- Success Story: Transforming Workflows with Continuous Improvement

- How to..Conduct 3S

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.