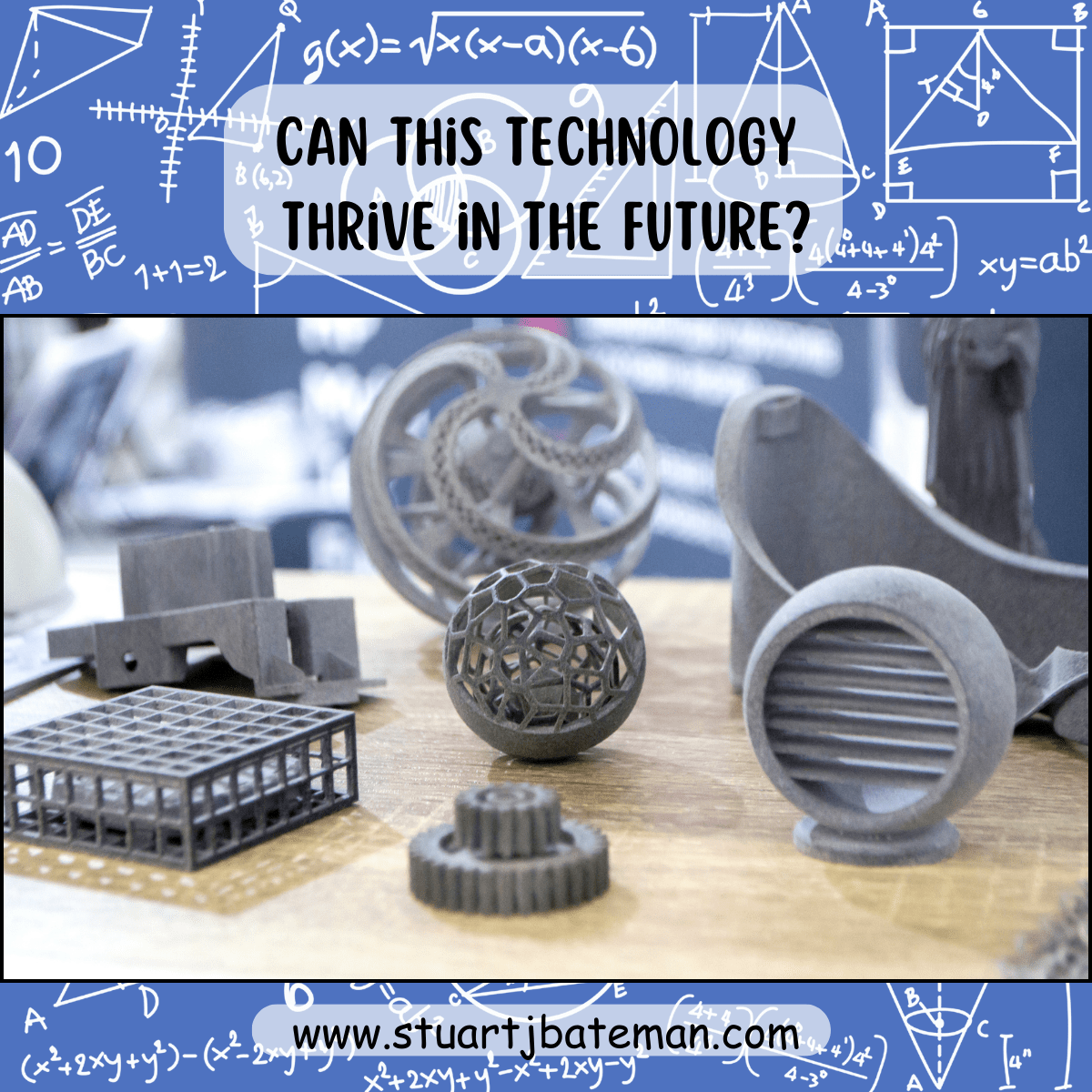

How Will 3D Printing Revolutionize Industries in the Coming Years?

3D printing is ushering in a new era of manufacturing, where imagination is the only limit to what we can create. – Chuck Hull, Inventor of 3D Printing

Question on 3D printing

“Can 3D printing overcome material constraints and speed limitations to redefine innovation in additive manufacturing, unlocking boundless potential for the future?”

That’s what I’ve been left to think about from this week’s question, well can it?

Let think about it’s scope:

• Diverse Design Possibilities: 3D printing, beyond its speed disadvantages, offers a broad scope for design innovation. The flexibility of creating intricate and customized designs tailored to specific manufacturing needs is a key aspect.

But for its future it needs to overcome several concerns:

• Material Limitations:

Challenge: Many 3D printers are constrained by the types of materials they can use. While there’s a wide range available, certain industries require specialized materials with specific properties.

• Speed of Printing:

Challenge: 3D printing can be a time-consuming process, especially for large or intricate designs. This limits its efficiency for mass production compared to traditional manufacturing methods.

• Post-Processing Requirements:

Challenge: Finished prints often require post-processing steps, such as sanding or painting, to achieve the desired surface finish. This adds extra time and effort to the manufacturing process.

• Limited Scalability:

Challenge: Scaling up 3D printing for large structures or mass production faces challenges related to cost, time, and the availability of suitable equipment. This is related to the speed issue, while they are slow we need more of them to create large print farms.

• Complex Design Software:

Challenge: Creating intricate designs for 3D printing often requires specialized knowledge and sophisticated design software. For me it’s more about having the specific knowledge of how to design for the part to be 3D printed without failures that result in time lost

But the benefits are huge, for example:

• Interplanetary Habitat Construction: Envisioning a future where 3D printing plays a pivotal role in constructing habitats on other planets showcases the technology’s potential in space exploration and colonization.

• On-Demand Tool Creation: The ability to manufacture tools on demand heralds a future where workshops could seamlessly produce necessary implements with minimal lead time.

I know this technology has a fantastic future with companies like Relatively space creating complex rockets from nearly 100% printed parts.

But what are your thoughts? do you share these concerns?

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.