Visual Management – A guide to easy implementation

The art of management – whether of society or a company – resolves around making informed choices about the allocation of resources.- The road ahead

Visual management overview

Visual management has been a foundation block to lean manufacturing since it was included in the house of Lean diagram that I’m sure all or you have seen (if not here it is).

But why is it a foundation block and what benefits do individuals and companies get from implementing it?

What is Visual management?

Simply put, visual management is a system where information is given to the person via colour or graphical means (there are text versions which are counted as SOP’s), that allow that person to continue their work or response to a situation or know what to do after reading that information.

This means, gone are the days when the 20 year veteran needs to be found so we know how to put part A into part B, it saves time while also sharing knowledge that could otherwise be locked away in someone who might not be at work today.

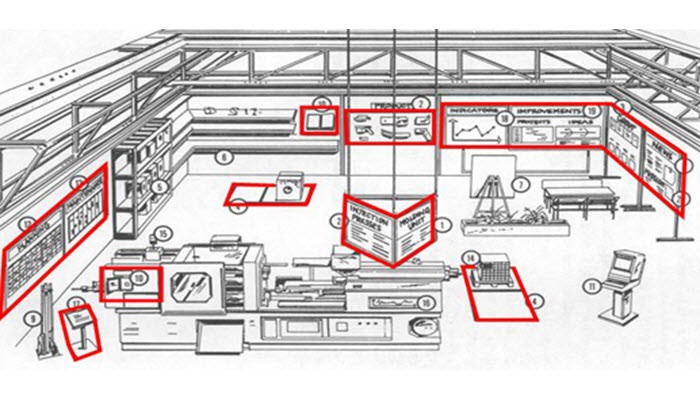

Visual management does go further than this, but at its heart is the ability to transfer information. There are studies (citation) that show that human respond quicker to visual ques over verbal or written ones, the images below will show you how much information can be portrayed so not to overload the viewer.

Benefits of Visual management

A quick Google search will pull up many benefits for this subject, so I won’t go into details here but highlight ones that I use to sell the idea to operators at work.

- Highlights dangerous places/activities or devices

- Translate information without having to speak to someone

- Store information, not having to had an expert on hand that know all

- Have signs/information in the right place for the relevant process

- Standardises operations

Examples of Visual management

Lets think outside the box of manufacturing and look at examples of everyday visual management that you’re likely to come across on your daily outings:

- Floor markings (shops)

- Colour coded fire extinguishers

- Fire exits

- Road markings

- Street signs

- Traffic lights

- Picture menus at McD’s

These will pop up everywhere once you know how to recognise what visual management is and the methods used to help guide people without the need for guides everywhere.

Where to get started and have a meaningful impact

The best place to start with visual management in my view is the floor followed closely be your inventory, always find out what systems within your production areas require managing and once you have a list start from the easiest.

- SOP’s

- Floor markings

- Kanban

- Safety areas

- Feedback charts (H&S, Throughput, Quality, Delivery, Growth)

Remember some of the best systems out there have very little complexity and yet they are able to communicate effectively, for example 3 year olds can follow LEGO instructions and as Humans we can recognise colours and picture faster than we can words, think about those and integrate them into your systems.

Where Visual management can go wrong

I have seen it myself, people going overboard with information signs /form and charts everywhere to the point where it just becomes noise. At this point you need to take a step back and think about a couple of things:

- What information is relevant to this area/department or process

- What extra information is universal and needs to be reiterated around the company

- What information is out of date and needs to be removed

It’s not a case of put up the signs and be done with it, unfortunately everything we done in industry is subject to change and with processes like Continuous improvement it’ll change and get better. But with that we need to be reviewing our Visual management solutions just like we do for SOP’s / Jigs & fixtures and Skills.

My experiences and conclusion

I always go back to my time at Stannah and to be fair out of the companies I’ve worked for, they were far in advance of their implementation of Lean methodologies (perhaps their investment abilities helped).

At Stannah we had the full suite of Visual management tools – From SOPs spread out at eye level on each flow line, to Kanbans that had labels on them indicating what to do if full or empty.

But the point I have to make, and this is what I’ve done at AI is that Visual management grows with the level of the Lean implementation you are currently at. While at the same time it also grows with the skill of your workforce and the level of demand/throughput in your production system. Take for example my 3 bin colour system that I implemented, we have no need for any more colour than 3 they manage the VMI (Vendor managed inventory) the bought out kanban and the in-house made parts.

Using just three colours and repeating those colours in the area where the bins need to travel to and from gives us a easy system to adopt with little failure, this helps easy people into the understanding of Visual management and the benefits of a organised and Lean system. (think of it as a quick win)

So, to end this piece I would recommend to you (or anyone) to go slow and start simple, you’ll find that Visual management once others understand it will also form part of your continuous improvement activities and will be improved itself!

Resources

https://txm.com/visual-management/

https://www.veryableops.com/blog/visual-management-manufacturing-logistics

Examples

Visual management for machines, maintenance and operations

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.