How to… conduct observational studies

“Figures don’t lie, but liars figure” – Statistics for dummies – Deborah Rumsey

What are Observational studies

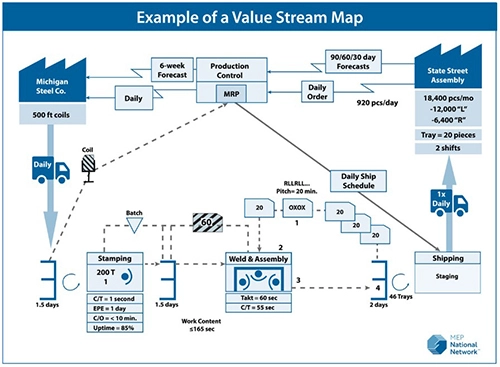

Before making changes to any process, we need to collect data based on the ‘current state’ which is used in the VSM later. Observational studies are exactly like what it sounds, a reasonable period of time where the engineer watches or even performs the task within the process/stage to gain a better understanding of what’s involved. This allows them to take notes and eventually ask meaningful questions with the experience of knowing the process to gain deeper understanding from those that work that stage every day.

Remember observational studies are a fact gathering activity so don’t take in what people tell you what the process does, go see it for yourself and document everything! – this in my view is different to the traditional Gemba walks which from my point of view is more watching then actually getting involved, and for an engineer to make any meaningful change / understand the process and assess the actual gains then roll up your sleeves and jump in!

In the example image below you will see the information that we are obtaining from the observational studies link the data in the boxes under the processes, but also for lean we’re understanding the wastes involved.

How to go about performing observational studies

To collect data, I have employed these various methods in the past and even though they are in no particular order, I tend to go top to bottom in this list.

- Gemba walks – Daily

- Conduct an audit of existing SOP’s or WI’s

- Spent time with the most experienced operator in the department to learn from them, doing their job and once you have enough from them, go choose the next process. Follow this pattern until you’ve experienced the entire production line, when improving later you can come back and focus on specific stages.

- Rewrite the SOP’s or WI’s with the help of each operator who practises the stage every day, and get them to prove read the SOP before putting it into general use

- Conduct Activity studies

- Conduct Time studies

- Create a Spaghetti diagram of the production line (WBS or Work breakdown structure are used later for SMED and Line balancing).

- Create a Machine – part matrix

- Conduct SIPOC

- Create a Swim lane diagram

- Interview operators

- Understand the ratio between NVA and VA for each stage and whole process

- Learn the route of all parts in the department and record it

- Learn the information routes in the department – what types of information devices are used

- Learn how operators move around when conducting process steps

- Understand the tooling / jigs/ fixtures/ gauges/ measuring equipment used

- Understand the IT systems employed and what their use it (what benefits do they have)

- Understand each part within the department – size / weight/ family it belongs to/ locations stored at

- Take photos of current setups

- Understand Demand for family parts so we can do a 80/20 analysis

- Understand the level of standardisation within the department, from produce / jigs/ training/ information and skills

- Note down any current data capturing systems

- If you haven’t already, then a layout of the factory/department and current benches / equipment and stock locations with dimensions

- Inventory levels

Why all this?

All this information will help us create new layouts / kanbans / VSM / Line balances / TPM and use other tools, so the more data collected up front the better we will understand the level of interactions between people the process, the level of complexity and the amount of variation we have to deal with before flow can happen.

When we come to monitor the processes, we’ll be able to measure the mistakes that happen due to the complexity and variation.

Thoughts on observational studies

When conducting these studies it’s best to discuss with all operators what you are doing and what the benefits are to them, as unfortunately Lean can have a bad name within some companies where it has been tried before and failed or worst been tried and succeeded which lead to a headcount reduction. (Lean isn’t about reduction in headcount, it’s an educational tool and those people where time has been saved are redeployed as Lean operatives to help engineers improve other aspects of the business, until demand increases because of savings being past to customers, that they go back to the line).

It’s also important to note, that we are only concerned about learning the current process and are not there to study the individuals, because they have had to adapt their habits to accommodate the practises, we need to understand why and what we can do to fix this. Remember that people will self-optimise themselves and not the whole system, as Production engineers we look at the systems with a view on its constituents and optimise the whole.

Deming spoke about the 94/6 rule 94% of problems can be traced to the process, but only 6% to the person. But often it is the person who is measured, not the process. Start with the assumption that it is the process that is broken and most times you will be right. Almost everyone has experienced negative measurement – errors, cost overruns, lateness – and almost everyone has responded by negative emotions – blame, threats, defensiveness. Most of this can be avoided if you start with the process not the person – so the manager, not the subordinate, needs to correct the process.

This is the view I have to remind myself to take, but it’s true that the people have to ‘use’ the process we put in place and if it’s not sufficient, they will make it so to the best of their abilities.

Conclusion

This stage will need to be revisited multiple times during the change process and creating flow, mainly to assess the changes and see if they are working, however keeping the operators informed as the changes progress is the other reason to visit often apart from double checking the original data was accurate (since some situations will be few and far between to show themselves).

We should also be collecting data on the original seven wastes : TIM WOODS, so by the end of this collection we would have data to describe the production area in terms of current state and current wastes, this will need to be prioritised so that the quick win wastes are removed first. This means reviewing the Activity study and Times study to understand the current efficient vs the ideal.

It is an undergoing to take on this stage conducting observational studies and the time taken will depend on the number of process steps, but the work up front will pay off in later activities.

References

- The Lean Toolbox – Bicheno & Holweg

- The Lean six sigma pocket toolbox – George, Rowlands, Price & Maxey

- The Goal – Eliyahu M. Goldratt

- Lean six sigma 36 hour course – Shaffie and Shahbazi

- The Machine that changed the world – Womack, Jones and Roos

- The Essential Deming – Orsini

External Lean – Resources

Want to learn more about Lean, then check out these 5 Lean organisation websites that I highly recommend:

Lean Smarts – LeanSmarts.com offers an online training academy designed to support lean manufacturing transformations through engaging video-based courses and certification programs Leanuk. The platform provides ready-to-use training materials with facilitator guides, covering topics like 5S, waste elimination, one-piece flow, pull systems, and visual management based on the Toyota Production System Leanuk. Organizations can deliver training through personal certification, facilitator-led sessions, their own training platform with up to 250 users, or integrate content into existing Learning Management Systems Leanuk.

Lean Academy – LeanUK.org (Lean Enterprise Academy) is a not-for-profit organization that helps individuals and organizations become self-reliant in lean thinking and practice through research, teaching, and coaching Leanuk. They conduct action research to develop learning materials and processes, deliver capability development through their online Lean Learning Platform and workshops, and share findings through events like the UK Lean Summit Leanuk. Founded by lean pioneer Dan Jones, they’ve been involved in developing and spreading lean thinking in the UK for over 40 years across industries including automotive, healthcare, government, and services Leanuk.

CI Tool kit – CIToolkit.com provides professionals, teams, and students with practical tools, methods, and resources for implementing continuous improvement and achieving operational excellence citoolkit. The site features libraries of downloadable infographics, team exercises and games for Lean and Six Sigma workshops, visual illustrations of concepts, and step-by-step how-to guides. It also offers digital products including training materials, templates, and worksheets designed to support continuous improvement journeys citoolkit.

iSixSigma – iSixSigma is a comprehensive online resource dedicated to Lean Six Sigma methodologies and continuous improvement practices isixsigma. The platform offers articles, case studies, and certification guides covering topics like Six Sigma, Lean manufacturing, Kaizen, and Business Process Management. It serves practitioners from beginners to experts seeking to reduce defects, improve efficiency, and drive business results through data-driven process improvement isixsigma.

Lean Production – LeanProduction.com is a free educational resource focused on lean manufacturing techniques and eliminating waste from production processes leanproduction. The site provides easy-to-understand guides on topics like 5S, TPM, OEE, and SMED, helping manufacturers improve efficiency, reduce costs, and increase productivity leanproduction. Brought to you by Vorne, it offers practical tools, templates, and resources designed to be quickly implemented by manufacturing teams looking to achieve measurable improvements in their operations.

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.