Navigating Complexity: A Practical Framework

The scientific mind does not so much provide the right answers as ask the right questions – Claude Levi-Strauss

Reducing Complexity: A Key to Efficiency

Complexity often stems from the number of interactions required to complete a task or understand a concept. The more intricate something is, the more time it takes to process, build, resolve, or evaluate. Thus, in manufacturing, as well as in various other industries and aspects of life, the benefits of reducing complexity have become increasingly evident. By simplifying, standardizing, or eliminating complexities, we can mitigate errors, misunderstandings, confusion, and misguided actions, thereby fostering a more productive environment.

According to Wikki,

“Complexity characterizes the behaviour of a system or model whose components interact in multiple ways and follow local rules, leading to non-linearity, randomness, collective dynamics, hierarchy, and emergence.”

Identifying complexity is essentially a matter of quantifying these interactions and determining the threshold beyond which it becomes too cumbersome for either an individual or a group to manage consistently.

Here’s a simple process to achieve this:

- Choose a task: Preferably one that consumes the most time, using Time studies.

- Break the task down: Break it down into its constituent steps (Work Breakdown Structure).

- Question each step: Determine their necessity. Can any steps be omitted while still accomplishing the task? Can they be redesigned for simplification? Is there a tool—software or hardware—that could streamline several steps?

- Streamline and Simplify: Remove unnecessary steps and implement changes as identified in step 3. Retest to ensure the task is now easier and can be consistently performed. If not, revisit step 2.

- Document the Process: Write down the revised procedure, ideally in a Standard Operating Procedure (SOP), for others to learn from. Revisit the process within a short timeframe to address any unforeseen issues that may arise.

While Lean tools such as Value Stream Mapping (VSM), Single-Minute Exchange of Die (SMED), and 5S can aid in process improvement, for design, the focus should be on eliminating features and standardizing components. Simplicity not only reduces the likelihood of breakdowns or failures but also facilitates ease of use.

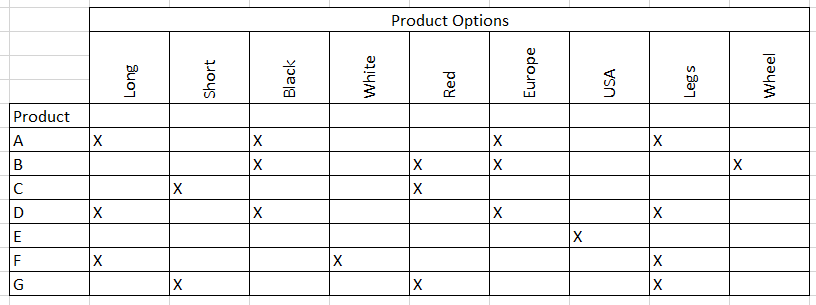

In manufacturing, the complexity often lies in the number of processes required to produce a part. Additionally, complexity arises in marketing, where companies offer various product combinations and variations. Utilizing tools like matrix-style tables to categorize product families against variations can help manage this complexity effectively in both manufacturing and marketing.

While it’s understandable that a company needs to make money, the more complex it makes its products the more demand it places on its supply chain to respond to a mix model schedule, depending on the size of a company they might not have the resources available to manage this, hence taking the hard decision to review their product variations and reducing them will have the largest impact on manufacturing, freeing up resources to increase throughput on high demand products.

Once that’s done and the company can grow, then re-introducing those variations (slowly) is worthwhile to compete in whatever market they are in.

While doing this it’s important to remember that the path of least resistance is where most people gravitate. Thus, simplifying processes often leads to greater adherence to work standards and improved efficiency.

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.