The power of Atomic habits converted into the best Tick sheet you’ll ever need

The less reliable information you have, the more inventory you need to build – Michael Hammer

What is a tick sheet?

A tick sheet is one of the methods we use in industry to collect data, this version of paper and pen is the low cost version before moving into the more advanced and more expensive digital versions of capturing data from the process.

This is one of the 7 quality tools with the others being:

- Stratification

- Control charts

- Scatter diagrams

- Histograms

- Pareto

- Ishikawa

Of these tick sheets are the form of data collection that the others require to enable them to give results, but there is an art in creating the best tick sheets.

The data we get back from tick sheets is count data or categorical data that comes in the form of yes/no pass/fail and how often, this is ideal to input straight into bar charts and histograms to understand frequency of the occurrence and into control charts to understand when they occur, with this and know where in our system the data is collected we can create measures to counter/remove those problems.

Why do we need them?

Simply put, data is the facts we need to base our decisions on and we need methods to collect it.

When we start a continuous improvement project, we usually start with a question that needs to be answered along with a set of assumptions, what is need then is to understand the current state of the system we are going to improve to see if those assumptions are correct and the question can be answered, if not then we use the data provided to base the next question.

Collecting data is also part of VSM (value stream mapping) and Measure in DMAIC, it gives us the baseline or benchmark so that we can compare any improvements we make, it also becomes an effective tool for the operators to communicate system problems and learn about manufacturing outside the normal area of just machine operation.

My method for creating tick sheets

Using Atomic habits guide below, I consider these points when creating a tick sheet –

✅ The 1st law (Cue): Make it obvious. – Keep the options to a min

✅ The 2nd law (Craving): Make it attractive. – Talk to operators to introduce the tick sheet format and decide on the style together

✅ The 3rd law (Response): Make it easy. – Design it in a way to maximise data but ensure it doesn’t take more than a minute to fill in each time

✅ The 4th law (Reward): Make it satisfying. – Create visuals based on the data to show operators that their information is being used to drive changes – this also comes full circles and teaches them at the same time

Pros and cons on Tick sheet

Before you set off creating a tick sheet, first consider the pros and cons in using them.

- Driven by the operator

- Operators need to be trained

- This process does need reviewing and policing to make sure the right data is coming in

- Low cost and quick to put together

- If made well, operators will respond with the data coming in quickly

- Does require an individual to convert the visual data into digital format for analysis

- Can be combined with scanners so data can be sent from any factory

- Best place to start when implementing continuous improvements

This list isn’t comprehensive, but you get the idea of the challenges and benefits that these sheets give you, be prepared to invest the time into these points to get the most out of them.

Examples

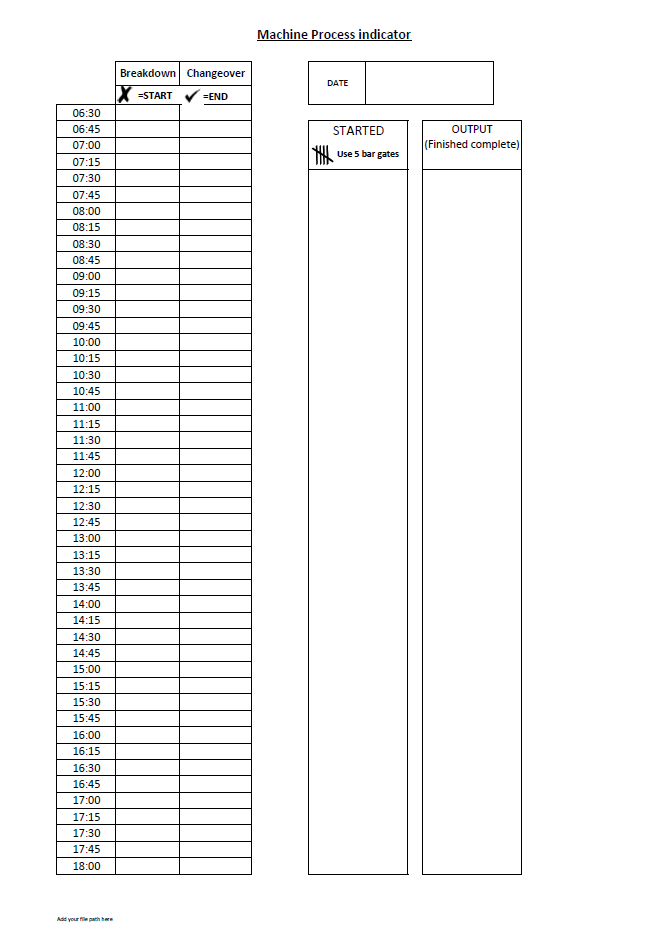

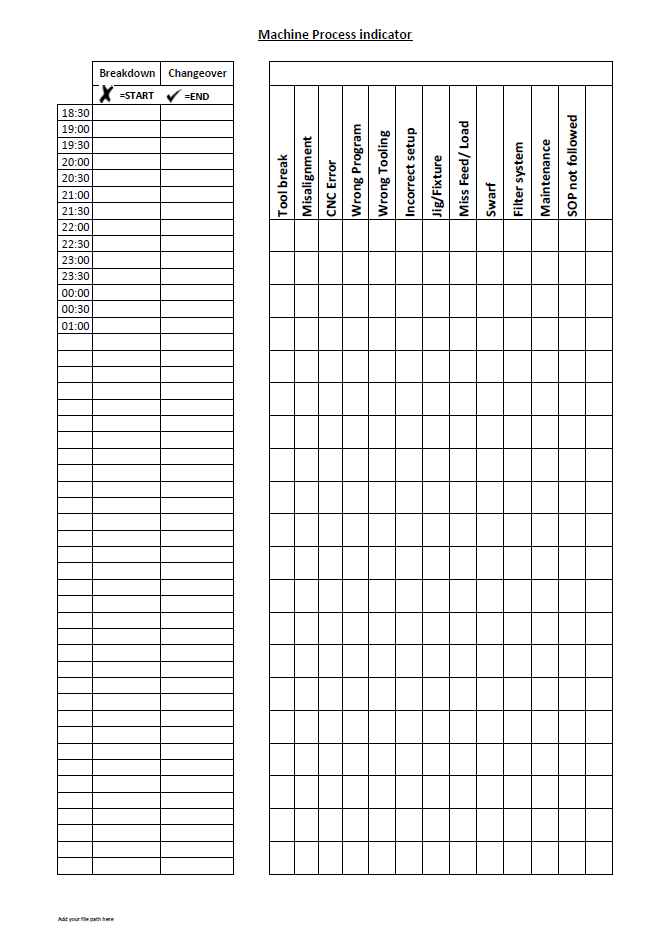

Here’s an example of a Tick sheet I created to monitor a flow production manufacturing line, this was one sheet per process that covered 10 machines, the operators were involved with its creation and approval of use.

Summary

Tick sheets should always be employed first to understand the system, answer the questions you might have and to collect data before investing in more expensive system that you probably don’t need.

By following the guide above you should be able to create your first effective tick sheet in a matter of minutes to show operators and get their feedback to refine it.

Resources for Tick sheet

As always, I’ve reviewed a few videos and sites that I like to recommend to you for further learning and understanding:

https://www.nikunjbhoraniya.com/2018/10/check-sheet-in-7-qc-tools.html

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools: