How to design and ask questions to investigate machine breakdown

The purpose of an organization is to enable ordinary human beings to do extraordinary things – Peter Drucker

So your machine broke down, now what?

When a machine breakdown occurs, it’s crucial to gather pertinent data right from the start. However, establishing a manual system to capture this data effectively from the shop floor can be challenging. A thoughtfully curated list of questions can significantly aid this process. By providing operators, who are usually the first to respond to breakdowns, with guided questions, you empower them to make accurate assessments quickly. This method not only decentralizes control but also assigns responsibility, allowing continued operations under guided assurance.

You don’t need to utilize every question for each incident. Select the ones that best address the uncertainties involved and are most likely to provide crucial information about the specific process or machine in question.

For common equipment like CNC machines, manufacturers often have extensive data on potential issues and their causes. Leveraging these questions can help you swiftly focus on and address the problem at hand. Similarly, if the breakdown involves a new or unique machine or technique, these questions can be instrumental in accumulating knowledge and developing a detailed fault tree.

A helpful list of questions to ask in the event of a machine breakdown

Here’s a comprehensive list that I’ve developed and used within several machine shops to enable good data collection.

Setup

- What was the condition of the workpiece before loading?

- What is the condition of the floor around the machine?

- Was there any changes to speeds and feeds?

- Were there any changes to the machine on the day of the issue before the fault?

- Maintenance?

- Environment adjustments?

- Operational alterations?

- Has there been any changes to the operation?

- New fluids?

- Filters?

- Cleaning?

- Tool changes?

- Was the correct program/tooling & workpiece loaded into the machine?

- Were the Work Instructions/SOP followed?

Technical

- Was the machine Vibrating during operation?

- Are there any fault codes on the screen?

- Is the issue Mechanical/Electrical or Software related?

- Were there any unusual noises from the machine?

- Has the machine been overheating on any parts?

- Are there any unusual smells coming from the machine?

- Have there been any abnormal sounds from the machine today?

- Are there multiple failures that occur at the same time?

- Can the problem be reproduced without loading a workpiece?

Work arrangement

- What was the condition of the workpiece before loading?

- How did the operator discover the issue?

- What was the sequence of events that led to the fault?

- Does the fault occur when the same stage of the process is performed?

Maintenance

- When was the machine last checked?

- Has any part of the machine been replace recently?

- Have the machine checks been performed today?

- Are there any notes in the service engineers report indicating potential concerns?

Operation

- What was the machine doing just before it stopped?

- How long since starting the operation did the machine stop?

- Was there any indication early that the machine was acting up?

Environment

- What is the temperature inside the factory at the time of the stoppage?

- What are the humidity levels on the day of fault?

History

- Has this particular issue happen before?

- Has the performance of the machine changed in the last few days?

How to turn this machine breakdown data into useful information.

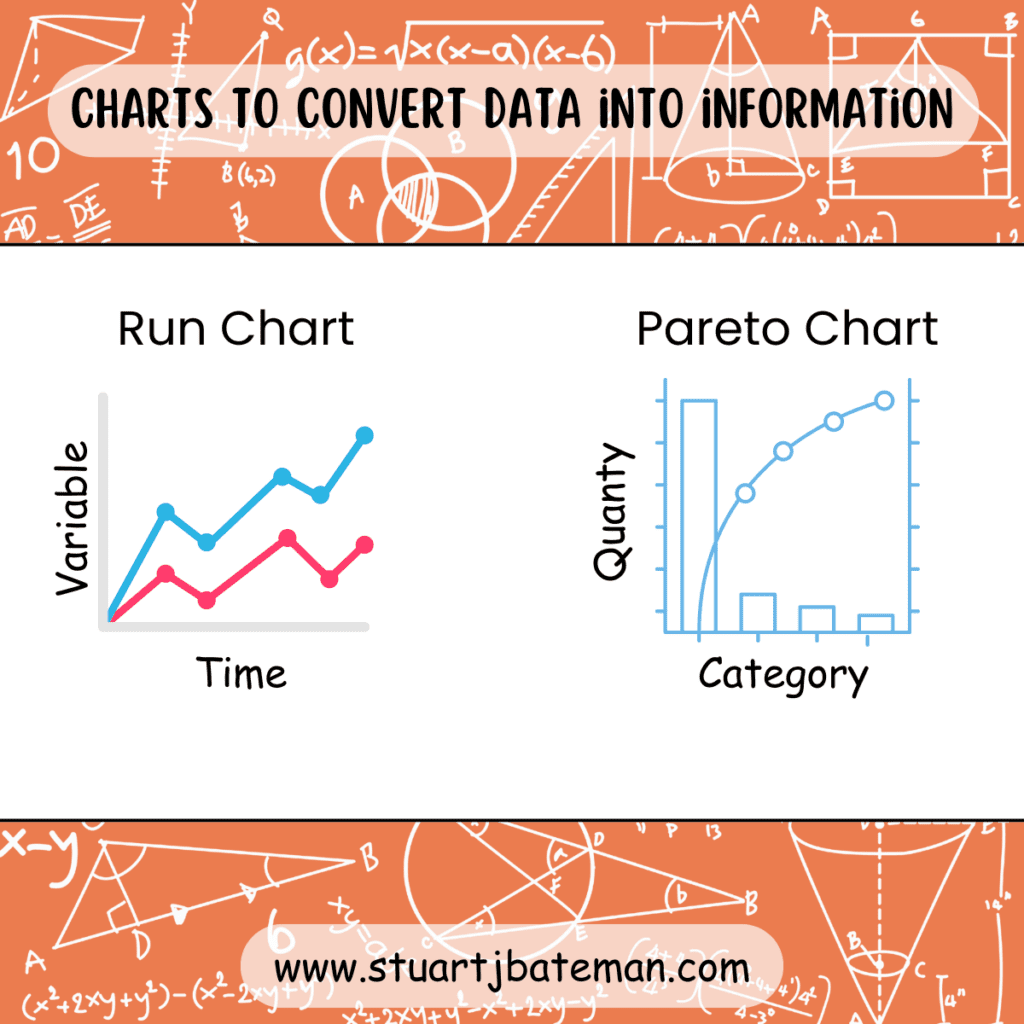

The best way I’ve found to translate the data is to design the capture document into a series of tick boxes, this removes the need for the written answer (unless it’s a value) and make it more of a categorical collection of ticks, over repeated uses of capturing the data it can then be analysed to see if any patterns appear. I would start with the run chart to see how often the machine fails/stops (frequency, how often and since when), then after that I use the best chart and use the Pareto method to identify the common occurrences during particular types of failures.

Next the data, this is only for those annoying reoccurring problems that you find hard to identified, these take time unfortunately for you to collect the data to find the patterns when certain problems arise that require you to just reset or bandage the machine to continue. The problem itself is not apparent and requires studying to understand the route causes.

Summary on machine breakdown.

While most breakdowns can be quickly identified and resolved, there will be ones that need further study.

Remember to ask questions like the ones above to help narrow down the issue, you may find that after reviewing several reports that there are more specific questions you can ask that relate to a particular problem, so go ahead and adjust the set of questions to dig deeper into your machine breakdown!

Resources to help.

https://www.hopenn.com/blog/what-to-do-when-your-equipment-breaks-down

https://zoidii.com/blogpost/troubleshoot-equipment-issues

https://www.linkedin.com/advice/1/how-do-you-diagnose-root-cause-equipment

https://www.skillcatapp.com/post/troubleshooting-ultimate-guide-to-fixing-machines

https://upkeep.com/blog/maintenance-troubleshooting-tips

https://www.ibm.com/docs/en/om-jvm/5.4.0?topic=support-introduction-troubleshooting

What are your thoughts? Have I covered everything or is there more you know and would like to share?

I’m always learning and improving this site and my blogs, so please feel free to get in touch with me via LinkedIn or this site to discuss any topics I have covered.

If you’re having trouble finding ways to progress check out these sites filled with free learning tools:

Discover more from The Chartered Engineer

Subscribe to get the latest posts sent to your email.